The scandal at Daihatsu Motors is worsening with each passing day. Faked safety tests were initially thought limited; they now appear to impact virtually its entire product line, forcing the shutdown of all its production facilities in Japan and jeopardizing the company’s reputation in all the markets in which it sells vehicles.

Investigations indicate that improprieties stretch as far back as 1989, indicating a profound problem with the company’s culture. An official investigation suggests that competitive pressures undercut one of the guiding principles of the Toyota group (of which Daihatsu is a member): that of “Genchi genbutsu,” or “Go and see for yourself,” the ongoing process of on-site learning and problem-solving.

Related: Daihatsu Faces Potential 100 Billion Yen Loss Amid Safety Test Scandal

This failure needs to be taken to heart not only by Toyota’s executives but also by all Japanese auto manufacturers. It is the latest of safety or other violations found at at least 5 of Japan’s major automakers in recent years. The country’s reputation as home to the world’s leading manufacturers is at risk if intensifying competition is driving its flagship companies to cut corners.

Daihatsu began its association with Toyota in 1967 with an investment by the automotive giant. Tokyo took a majority share in the company in 1998 and it became a wholly owned subsidiary in 2016. Within the conglomerate, Daihatsu concentrated on producing smaller vehicles such as minicars, some sold in Japan but with a focus on Southeast Asian countries like Indonesia and Malaysia as well as other emerging markets. It also makes cars for other manufacturers such as Mazda and Subaru under original equipment manufacturer (OEM) arrangements.

Daihatsu accounts for about 4% of the Toyota group’s global vehicle sales and generates about 7% of its total group revenue and 3% of its profit. Those numbers were expected to grow substantially this year, but then scandal hit.

Daihatsu began to suspect a problem this spring that concerned the testing of door linings and requested a third-party investigation. Initially, it found flaws in safety tests for six models. A follow-up revealed more extensive problems: data falsification and the use of unauthorized test procedures. Daihatsu now acknowledges 174 examples of misconduct including tampering with test results of airbag control units and vehicles that affect 64 models and three engines, including some sold under the Toyota brand. The misconduct stretched back decades but reportedly increased after 2014.

Related: Dutch Firm to Claim €50 Million in Damages from Daihatsu

Following the revelations, Daihatsu announced that it was suspending all vehicle shipments. And then a week later said it would shut down all production facilities in Japan. The Ministry of Land, Infrastructure, Transport and Tourism, which oversees the industry, ordered Daihatsu to stop shipping vehicles until it conducts its own investigation. The precedent suggests that could take a couple of months.

The impact of the shutdown will be felt throughout the entire auto industry. Daihatsu assembled about 870,000 vehicles in fiscal 2022 and its supply chain includes over 8,000 companies with sales of about ¥2.2 trillion ($15.53 billion). The company has said that it will compensate the 423 companies it directly supplies, as well as dealers, and will ensure that the 9,000 workers at its Japan factories will not suffer. Total losses could reach as high ¥100 billion.

Company officials acknowledge that the misconduct is a failure of management and executives failed to monitor the factory floor. Toyota Executive Vice President Hiroki Nakajima explained in a press conference that:

“Genchi genbutsu is the most important concept for us, but we realize once again that we were lacking in this area.”

The problems appear to extend beyond Daihatsu. Last year, there were reports that fuel economy and emissions standards tests had been modified at truck maker Hino Motors and forklift manufacturer Toyota Industries, while Denso, a supplier of auto parts, has been recalling defective auto pumps. Earlier this month, Honda announced that it was recalling 2.6 million vehicles in the United States because a Denso fuel pump could cause engines to stall.

Related: Hino Expelled from Toyota-Led Commercial Vehicle Partnership

That same defect led Honda, Toyota, and 6 other automakers to recall more than 3.8 million vehicles since March 2020. All three companies — Hino, Toyota Industries, and Denso — are part of the Toyota group.

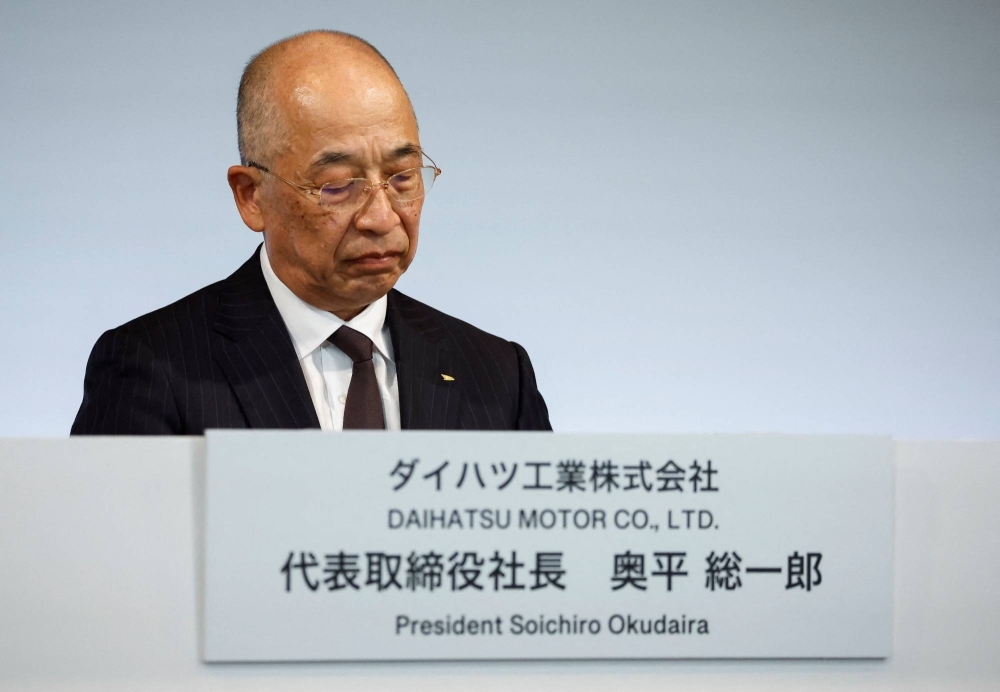

In the Daihatsu case, investigators believe that the problem reflects increasing pressure brought upon management and workers as a result of intensified competition. Daihatsu President Soichiro Okudaira admitted by saying:

“We have neglected to understand the burdens and hardships faced by employees as they developed vehicles on a short-term schedule and created a corporate culture that cannot abide by legal rules.”

To his credit, he didn’t try to avoid the blame. He added that “management is fully responsible for this.” Toyota’s Nakajima specifically pointed to the increase in OEM arrangements which “may have significantly increased (Daihatsu’s) burden in the development and testing sites.”

The problem is not Toyota’s alone. Five of Japan’s major automakers have been charged with safety and other violations in recent years. This either reflects the attitude of a new generation of workers that is not as committed to its work product as that of its predecessors or competitive pressures that force companies to cut corners and take shortcuts. Either way, management has not kept an eye on the factory floor and allowed these practices to take root.

Related: Hino’s Widening Engine Scandal Becomes Big Headache for Toyota

Companies must become attentive to the humdrum, costly but also critical need to enforce compliance measures and codes of conduct. This may seem like bureaucratic red tape, but safety and emissions tests and standards are not optional. Safety in particular is a priority for automobile buyers.

The cost of this scandal will be high. Mitsubishi Motors lost nearly ¥200 billion in fiscal 2017 after it faked fuel economy data. Daihatsu and Toyota can afford a similar hit to their bottom line, but both will be lucky if that is the extent of the damage. Daihatsu was the spearhead of Toyota’s efforts to sell in Southeast Asian markets. This scandal calls that strategy into question.

The reputational cost that they will suffer is much harder to calculate but is no less important. Nor is the impact theirs alone. Japan has a hard-won reputation for superiority in the manufacturing process. This image has spilled over into all the nation’s products. This series of scandals threatens those accomplishments.

Japan’s manufacturing powerhouses must ask themselves if they have become complacent. It is time for introspection and self-correction. Japan’s future lies in the balance.

Source: Japan Times

A computer animation professional with over 23 years of industry experience having served in leading organizations, TV channels & production facilities in Pakistan. An avid car enthusiast and petrolhead with an affection to deliver quality content to help shape opinions. Formerly written for PakWheels as well as major publications including Dawn. Founder of CarSpiritPK.com