Sumitomo Rubber Industries has teamed up with Kansai University to develop a method of harvesting electricity from the rotation of a tire. Indeed it’s a completely different take on electrification.

Related: Nissan Unveils Brain-to-Vehicle Technology to Prevent Accidents

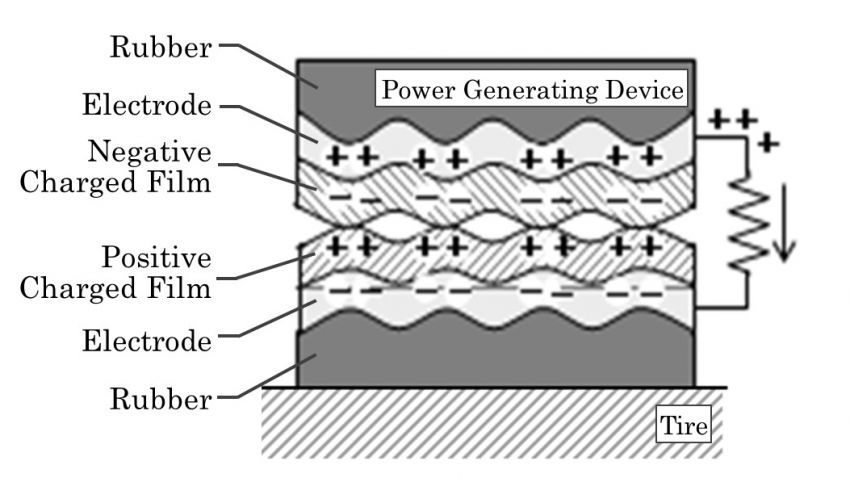

According to information, the harvester gets its electricity from frictional charging, a form of static electricity which is generated when a tire deforms as it rotates along a road surface. This is done with electrodes on rubber pieces for the tire and power-generating device respectively. Electricity is generated through oscillations between the positive and negative-charged films.

The benefit is a power source for sensors such as tire pressure monitoring systems (TPMS) and other automotive devices and digital tools without additional reliance on a car’s batteries or electrical architecture. And in case of electrified powertrains, it will also help increase battery driving range.

Related: Future Toyota Vehicles to Have A Nasty Surprise for Carjackers

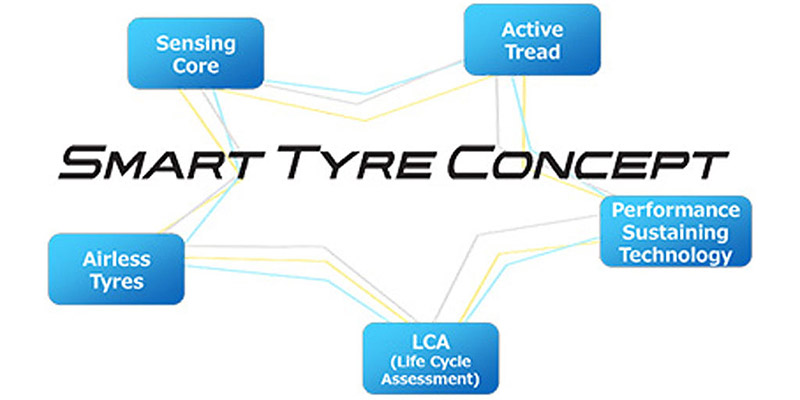

Sumitomo Rubber Industries is the name behind popular tire brands including Dunlop and Falken. Sumitomo previously unveiled the Smart Tire Concept at the 2017 Tokyo Motor Show, which was a collection of ideas slated to be unveiled in stages over the next few years.

These included Sensing Core, a software package that aims to use tires as sensors for the monitoring of road and tire conditions based on changes in the rotation speeds of each tire; active tread, which aims to adapt the grip qualities of tire rubber to work better in prevailing conditions such as water or ice; airless tires, which do away with the need for tire pressure management; and life cycle assessment for the tires’ environmental-friendliness over the entire lifespan, from manufacture and shipping via usage, to recycling.

A computer animation professional with over 23 years of industry experience having served in leading organizations, TV channels & production facilities in Pakistan. An avid car enthusiast and petrolhead with an affection to deliver quality content to help shape opinions. Formerly written for PakWheels as well as major publications including Dawn. Founder of CarSpiritPK.com