Japanese companies that once dominated the market for automotive battery materials have been knocked from their perch by cheaper Chinese rivals, but they hope new technologies and recycling will let them reset the playing field.

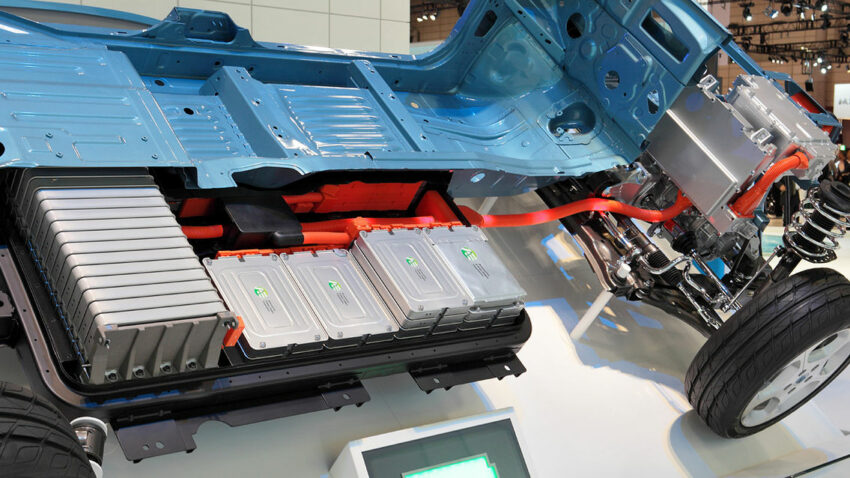

Batteries account for about one-third of the price of an electric vehicle, and producing them cheaply is a major factor in whether an EV (electric vehicle) model can compete on the market. A group of Japanese automakers including Toyota and Nissan, materials companies like Sumitomo Metal Mining and major trading houses came together last April to form the Battery Association for Supply Chain (BASC), aiming to ensure a stable supply of car battery materials.

Related: Toyota Ranked as World’s Third-Most Obstructive Company Against Climate Policies

The cross-industry partnership came about under market pressure from Chinese players that have surged to prominence in the global battery supply chain. “China is tough to compete with on price. It’s a difficult battle,” said Isao Abe, the Chairman of BASC and General Manager of the battery materials division of Sumitomo Metal.

Japan, home to Toyota, with its global hybrid vehicle push, and Nissan, a pioneer in electrics were the ones to beat until the early 2010s. Japanese companies once held the biggest market shares for each of the four main battery components: anodes, cathodes, separators and electrolyte. Now, Chinese rivals are on top in three of these categories.

Related: How Toyota Sneakily Spreads Anti-EV Propaganda in Japan

Cathodes are the exception. The positive terminal can make up half the cost of a battery, containing pricey metals like lithium, nickel and cobalt that require advanced technology to work with. Sumitomo Metal holds a 49% market share for the nickel cobalt aluminum (NCA) cathodes used in Tesla’s flagship models. These cathodes “have earned high marks for safety and range,” said Akira Nozaki, Sumitomo Metal’s president.

The problem is procuring the necessary metals. The ores are not found in Japan, and intermediate products that have been processed to a higher degree of purity are difficult to source as well. Japan relies on China for about 80% of its lithium hydroxide, for example. “Low labor and electricity costs” have enabled China to gain an advantage, a BASC representative said.

China is not the only concern. Russia produces about 10% of the world’s nickel supply, led by Norilsk Nickel, the world’s top nickel miner and is the second-largest producer of cobalt. Fears of a supply crunch after Moscow’s invasion of Ukraine drove nickel prices to double their level a year earlier, and cobalt prices have been elevated as well.

Related: Global Market Share of EVs Reach 9%- Highest Ever!

This has stoked interest in lithium iron phosphate (LFP) cathodes, which do not use nickel or cobalt. Though they are less energy-dense than NCA batteries, they cost less to produce. Automakers including Volkswagen have opted for LFP batteries. Chinese manufacturers hold a near-monopoly on LFP cathodes, which Tesla already uses for its entry-level model. CEO Elon Musk has said he anticipates a long-term shift in the market toward these batteries, “probably to two-thirds iron, one-third nickel, or something on that order.”

That shift would deliver a further blow to Japanese materials makers. If buyers base their decisions on cost, “Chinese players will quickly displace Japanese companies”, said Satoru Inubushi, a Managing Director at Nichia, which once enjoyed a 20% share of the cathode market. “They’ll have the battery market under their thumb.”

Related: Toyota CEO Akio Toyoda is Dissatisfied with Japan’s Push Towards EVs

Japan lags even further behind in other components. China accounts for about 60% of the global supply of fluorite ore and is a major production center for a compound made with fluorite that is used in electrolyte. China is home to the world’s top three electrolyte producers. “We don’t plan on competing in terms of production capacity,” said Masaaki Tsuchiyama, CEO of fourth-ranked MU Ionic Solutions, a joint venture between Mitsubishi Chemical and Ube Industries. Japanese producers are also at a disadvantage in anodes, given their reliance on China for graphite, a core component. China produces over 50% of the world’s natural graphite, as well as a large portion of the synthetics.

Some Japanese companies are partnering with Chinese players rather than competing. Asahi Kasei, the world’s second-largest producer of battery separators, has teamed with top-ranked Shanghai Energy New Materials Technology to bring a new factory online in China this year.

Related: BYD will Supply Blade Batteries to Tesla, Toyota, Suzuki & Daimler

China has become a major producer in all four key battery components, thanks to Beijing’s aggressive subsidies to promote new-energy vehicles. Chinese automakers were able to devise more concrete production plans with the government’s support, which in turn let materials makers invest more effectively.

Though Japan also looks to promote electric vehicles, the government has yet to lay out a detailed strategy. “It’s hard for us to increase production unless there is a guarantee that our products will sell,” said a leading Japanese battery material maker. One option for Japanese producers is to continue investing in new capacity to defend their global share in high-performance materials. Sumitomo Metal said in February that it will triple cathode production capacity to 15,000 tons monthly by the end of March 2031 compared with the just-ended fiscal year. Nichia will consider increasing production of cathode materials.

Related: BYD to Help Toyota Build a Cheap EV Sedan

Demand for recycled materials is growing as well. Under guidelines proposed in late 2020, the European Union will require EV batteries to contain at least 12% recycled cobalt and 4% recycled lithium and nickel by 2030.

Japanese companies lead the world in battery-related recycling technology. JX Nippon Mining and Metals is expected to start producing cobalt sulfate as early as summer, while Sumitomo Metal has developed the first method of its kind to cheaply extract copper, nickel, cobalt and lithium from old EV batteries, which could be reused in battery electrolytes.

Related: EVs in China are Cheaper by 47% Since 2011

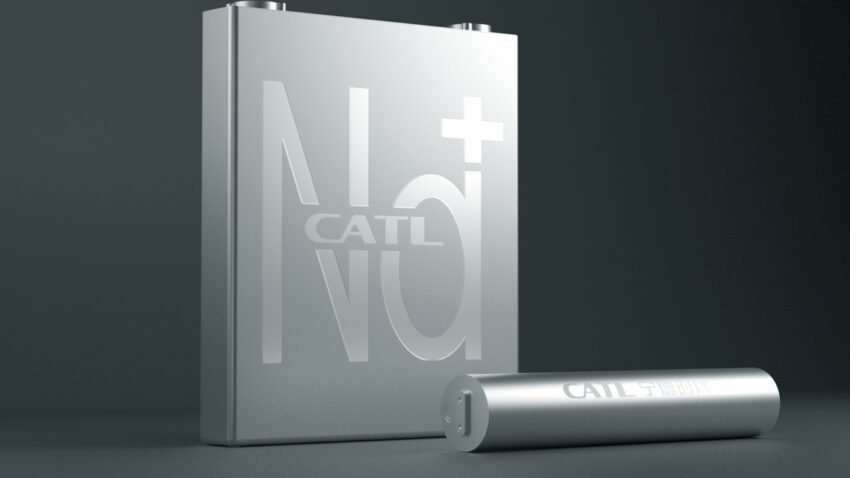

Yet China is fast catching up here as well. A unit of Contemporary Amperex Technology (CATL) is investing up to 32 billion yuan ($5.04 billion) to open a recycling facility as early as 2027.

Next-generation batteries may be the key to the future of Japan’s battery materials industry. Sumitomo Metal, Mitsui Mining & Smelting and others are developing cathode materials for solid-state batteries, which Toyota and Nissan look to incorporate into their EVs. But Nissan’s solid-state battery models are not expected to go into mass production until fiscal 2028. CATL plans to commercialize sodium-ion batteries by 2023, meaning they and other cutting-edge cells could take over the market in the meantime.

Related: CATL Unveils Revolutionary Sodium-ion Batteries

Three decades since Sony brought the world’s first lithium-ion batteries to market, the global battery industry is now largely controlled by Chinese producers. Still, some remain bullish about Japan’s prospects. “The U.S. and China are decoupling their supply chains, and cheapness won’t be the only way to measure value in the self-driving age,” a BASC director said.

Source: Nikkei Asia

A computer animation professional with over 23 years of industry experience having served in leading organizations, TV channels & production facilities in Pakistan. An avid car enthusiast and petrolhead with an affection to deliver quality content to help shape opinions. Formerly written for PakWheels as well as major publications including Dawn. Founder of CarSpiritPK.com