According to multiple media reports, BYD is expected to supply Tesla with its state of the art Blade batteries. Moneyball and CnEVPost have also reported that the deliveries will start in the Q2 of 2022, while the batteries are currently undergoing testing.

“Multiple insider sources: #BYD to supply Tesla with blade battery starting 22Q2, Tesla model carrying BYD #battery entered C-sample testing phase.”

There are various chemistries of Li-ion batteries available, however the most common types are the lithium ‘metal’ oxide (where the metal can be NMC [nickel-manganese-cobalt] or NCA [nickel-cobalt-aluminium], among others) and lithium ferrous phosphate (LFP). While NMC batteries have remained the preferred choice for Western automakers such as Mercedes-Benz, BMW, Volkswagen and Ford, the LFP chemistry has found favor with Chinese automakers.

Related: BYD Destroyer 05: Newest Plug-In Hybrid Chinese Sedan with a Badass Name

BYD’s Blade batteries are based on the LFP chemistry. They are incredibly long, measuring 96cm in length, 9cm in height and just 1.35cm in thickness. BYD claims that its Blade batteries are superior to conventional LFP cells.

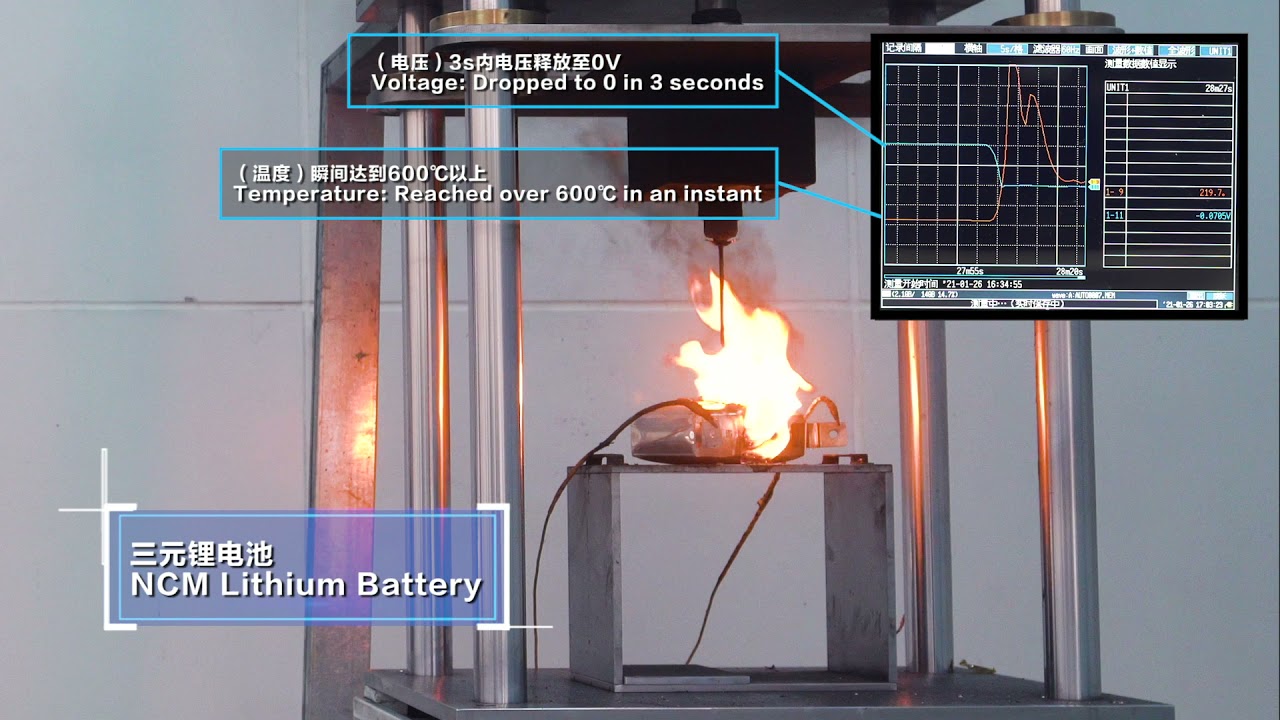

NMC batteries have been widely criticized for their safety risks and the potential for spontaneous combustion in case of accidents. The cobalt content in the batteries minimizes the fire hazard, but with the element being expensive, difficult to ethically source and infamous for being unfriendly to the environment, companies are hard at work to reduce the amount of cobalt in their batteries, and, instead, increase the nickel content. While this does help to substantially increase their energy density, it also makes the batteries more prone to combustion, in case of a mishap.

Related: Toyota Set to Launch its Solid State Battery in 2021

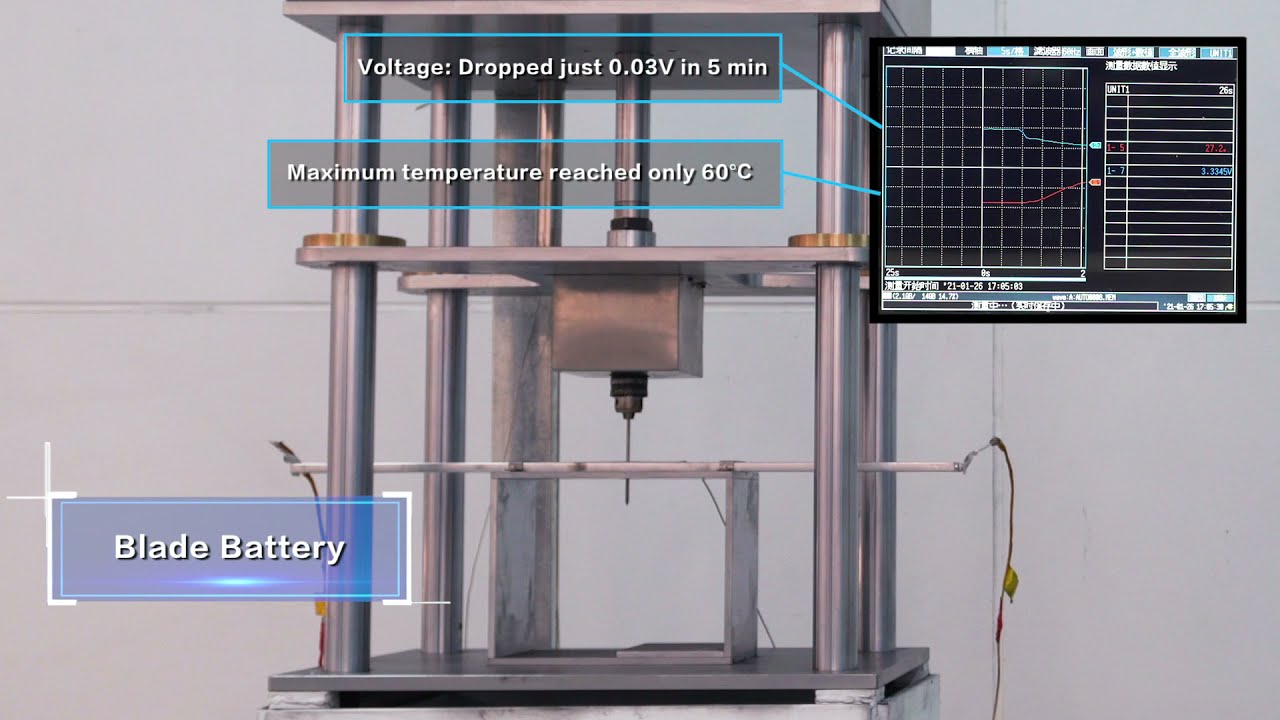

The LFP batteries are generally much safer, but BYD claims to have gone a step further with its version in the Blade cells. It says that during nail penetration tests – considered to be one of the most stringent in assessing battery safety – the surface of the Blade cells only reached a temperature of 30-60deg Celsius, without any signs of smoke or fire.

The Chinese automaker further states that under similar conditions, conventional LFP batteries had a surface temperature of 200-400deg Celsius, while ternary (NMC) batteries not only exceeded 500deg Celsius, but also “violently burned”. BYD goes on to state that even in other tests, where their batteries were “crushed, bent, heated in a furnace to 300deg Celsius and overcharged by 260%”, there were no incidences of fire or explosion.

Blade cell testing

NMC cells are said to have an energy density of 200-250Wh/kg, which is much higher than that of LFP. But the latter have a distinct cost advantage, since they don’t use expensive metals like cobalt and nickel. BYD has adopted a ‘cell-to-pack’ architecture for its Blade batteries, which is touted to have made them even more economical, in addition to improving their energy density.

Related: BYD Aims to Become Second Car Company to Reach 1 Million EV Sales in a Year

For the uninitiated, the battery pack of any electric vehicle is structured in a manner where a cluster of individual cells is put into a frame to protect it from heat and vibration – this unit is called a module. A number of modules grouped together form a battery pack. Boasting of increased safety, BYD has decided to skip the module phase and directly integrate its cells into a battery pack. With lesser packaging involved, the whole pack is cheaper and also slimmer and lighter, resulting in a higher energy content at the pack level.

Tesla already uses the LFP batteries in its entry-level Made-in-China Model 3 and Model Y, but those cells come from CATL. However potential use of BYD’s batteries might be related to the upcoming “cheap” Tesla model that could start at around $25,000. Rumors say that Tesla already has a prototype of it.

Related: BYD Wins Chile Lithium Extraction Contract for $61 Million

In another report, the BYD Blade batteries are said to be making their way into Suzuki and Toyota EVs, as the two Japanese automakers are in process of introducing their first electric SUVs in India. As per reports, Suzuki (Maruti) plans to be extremely price competitive with its midsize electric SUV that is expected to be positioned in the INR 13 to 15 lac range, something that could be made possible due to the lower costs of BYD Blade cells.

The Chinese automaker which considered pioneer in EVs and battery tech will also help Toyota build a low-cost electric sedan that is expected to make its debut as a concept later this year. In addition BYD is also rumored to be supplying its Blade batteries to Daimler AG of Germany. BYD and Daimler already have a joint venture in China and a luxury, niche EV brand called Denza. There was a rumor that Ford is also willing to partner with BYD in China.

A computer animation professional with over 23 years of industry experience having served in leading organizations, TV channels & production facilities in Pakistan. An avid car enthusiast and petrolhead with an affection to deliver quality content to help shape opinions. Formerly written for PakWheels as well as major publications including Dawn. Founder of CarSpiritPK.com